Steam Cooker - Solar

Solar Steam Cooker

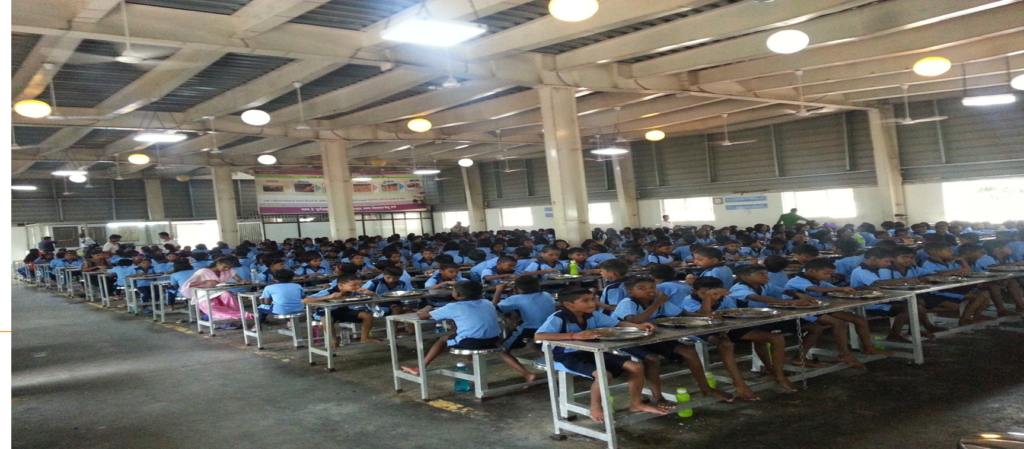

Solar steam cooking system can cook food for several thousand persons at a time. The system uses automatic tracking solar dish concentrators which convert water into high-pressure steam and consists of shell-type receiver made of mild steel, 35 cm in diameter, connected to two concentrators on either side, which focus sunlight on both sides of the receiver. Several such receivers are connected to a 12” dia header pipe which is half-filled with demineralized water. The receivers and the header. Each receiver is integrated with two pipes of 1 ½” and ½” diameter from inside, which pipes are insulated to avoid any heat losses that help in the thermo-siphonic flow of water from receivers to header and back. When the water gets heated in the receiver, it starts moving up in the header through one pipe and the cold water from the header starts coming into the receiver. The cycle goes on and high-pressure steam is generated in the header pipe after some time.

DESCRIPTION

Working of the System

Before the system is put into operation in the morning, all the header pipes are half-filled with water using a high-pressure reciprocating pump. All the concentrators are then arranged manually in the direction of the sun with the help of a central tracking arrangement. Once this is done, all the concentrators then track the sun automatically with the help of a small DC motor run by PV panel. A timer relay is used for adjustment of tracking time relay. The steam pressure starts building up in the header pipes immediately and is sufficient to deliver the steam to the kitchen in an hour or so. This steam can be drawn any time in the day even at the time of power failure as the feedwater pump is not required to feed water and push the steam. An oil-fired boiler can be connected to the system to ensure that the required steam is always available in the kitchen if the sunshine on a particular day is not adequate.

Economics (Tentative)

Cost of cooking system for 1000 people is about Rs.80 lakhs. (Special workshop facilities are required at site for installing the system besides back up boiler and cooking utensils.) MNRE provides capital subsidy upto 30 % of the cost. Saving in fuel cost (furnace oil) would be about Rs.20 lakhs / year. The payback period varies from 7 to 8 years depending upon size of the system.